How To Do A Risk Assessment

Today we will explain how to do a risk assessment. we will cover all elements related to work permit risk assessment.

Definition of Risk assessment:

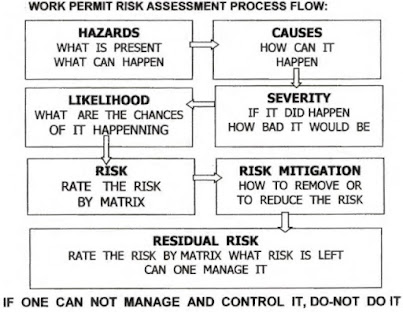

All activities have an element of risk that has to be managed. In refinery operation and maintenance, the risks are many, high in both probability and consequences, unless adequately managed. Managing these risks by adopting and employing work permit risk Assessment methods are therefore the essence of controlling loss. This can be done by following steps:

1. Identify the hazard.

2. Assess the risk

3. Put controls/safe guards in place

4. Re-assess the risk with control in place.

5. Confirmation of reduced risk.

Hazard:

A condition with a potential for accidental loss.

Risk:

A measure of how likely and how serious an incident can be. It comprises of two Components.

1. Likelihood – What are the chances of it happening?

2. Severity- If it did happen how bad would it be?

Who will do it?

People who control or carry out onsite jobs, and use work permits to do so are the People who should conduct work permit risk assessment. They shall be thoroughly and formally trained in all aspects of work permit risk assessment and be able to demonstrate full understanding and practical application; in other words they shall be made competent.

· Team led by Area section head/senior engineer.

· Area safety engineer

· Concern job engineer.

· Shift supervisor and any other engineer if necessary.

When It Is To Be Done:

Work Permit Risk Assessments shall be done for all critical jobs. It shall be done before the job is started.

How it is to be done:

It is done by using a simple matrix chart. LIKELIHOOD of occurrence of an event is given horizontally at the bottom and SEVERITY of the consequences vertically on the side in the matrix chart. The block, where they meet is the RISK LEVEL. The RISK levels have been graded in the chart and colored RED, YELLOW, BLUE & GREEN in the order of reducing severity. The purpose of assessment is, after identifying the risk level. Take measures to remove or reduce risk to an acceptable level “CARE” by

· Employing controls / safeguards.

· Doing the job in different ways.

(If one cannot reach acceptable level, Do not do it)

To

start the process, one must know the job, then identify the hazards,

decide likelihood and severity, and see what the risk level it shows on

the matrix chart. If it’s too high (not acceptable, i.e. caution, alert

and alarm), one then decides what one can do to reduce it (mitigation).

Then try with the matrix again. If it’s reduced to acceptable level

(“CARE”) then the risk assessment is completed. See the matrix and

process flow diagram).

Risk assessment shall be documented and

be retained for future use. If it is being used again, it must be

reviewed to ensure that nothing about the job has changed and it is

still relevant.

One must apply following actions at each level:

CARE: One can proceed with the job.

CAUTION:

Consult your supervisor for advice, re-assess

if required, put additional controls to bring down level to CARE

ALERT: Stop, advice supervisor, who should consult his superiors

ALARM: Stop, this is too dangerous, it needs to be fully reassessed.

No comments:

Post a Comment